Customer testimonial letters

Denneman BV (Hydraulics, transmission and fuel )

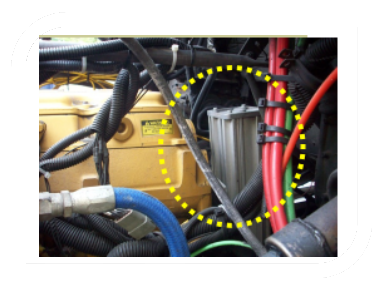

Since 2007 we have been installing NTF micro filters on both the transmission and the hydraulic and fuel systems of all our tractors and excavators.

Before we started using NTF filter systems, we regularly had problems with the hydraulic installation of our machines.

Dirty oil caused poorly closing valves and a jerky operation with stationary machines and costly hydraulic repairs as a result!

As soon as we started using NTF filter systems, these failures were a thing of the past and our machines are again 100% reliable.

Not only the repair costs went down but also our fuel and oil consumption.

We now have machines driving around with thousands of operating hours without oil change.

We only add oil.

Ground support equipment Airports TCR (hydraulics)

TCR is one of the largest company offering a unique and comprehensive range of GSE services that supports customers in a vital aspect of their ground handling processes: the use and operation of their GSE. TCR is headquartered in Brussels and has local offices in Paris, London, Amsterdam and Madrid and many more 14 country in total.

TCR Customers base comprises European largest airlines, handling companies, integrators and cargo handlers.

Employees: 300 staff GSE fleet for rental: 6000 units

ESD Silicon Carbide (fuel, engine, hydraulics)

In 1996 ESD decided to replace two Komatsu caterpillar taps with Volvo EW 150 mobilecranes as they were much cheaper in maintenance.

The wear and tear of the caterpillars.

Silicon Carbide gives a high wear image on our machines.

In the Volvo a Perkins engine was placed with a centrifugal fuel pump with which we could not even run for 1000 hours, because of the fine silicon dust, which is widely available, and therefore also with the fuel in the tank sneaks and by the original filters came into the pump, the pump was not offered a

long life.

Wagenborg Nedlift vertical transport equipment (Engine)

Wagenborg Nedlift offers a wide variety of vertical transport equipment and owns a modern and divers fleet of over a hundred units.

From single lifts using one hydraulic crane to complicated projects Wagenborg Nedlift is using NTZ micro filtration on the engines of its cranes for over 15 years Jan Winkels chief Technical Department: We apply NTZ bypass filtration on the engines of our cranes since

Westtrac New Holland, Case, Steyr Dealer Agriculture (hydraulics, transmission)

We have been installing NTF installations for over 5 years. Previously, we regularly received complaints about electrical valves and electronic remotes valves. Therefore we went on a search for a fine filter installations and we ended up at NTF. We then sold this optional fine filter system.

On all vario-controlled transmissions The customer also experienced the benefits and after some time of finer filtering and based on good experiences, they considered the installation of an NTF fine filter as a normal thing to do.

Less problems with valves and controls and the oil itself remained visibly cleaner. As a result, this is now sold as

a standard system.

There are about 150 tractors of New Holland, Case and Steyr with an NTF filter installed, sold each year.

Power generating units Enerson F.G. Wilson (Engine)

We inform you that your micro oil filter for thermal engines has met the requirements as set by by the French Army for all power generating units installed in Kosovo, Bosnia, Afganistan and on different locations of peace enforcement troups.

The installation of this bypass microfiltration allowed; – an increase of the mechanical reliability in particularly hard conditions at these locations – easier maintenance and a considerable cost reduction – extended drain intervals and a greater availability of the machines.

The majority of the machines has already been in service for over 20.000hr

Customer Testimonial truck Caterpillar Model 3406E (Engine)

In January 2000, David Stufko installed an NTF Bypass Engine Filter on his rig to extend his oil drain interval and keep his engine clean.

He didn’t realize how valuable the filter would end up being.

Then in March 2001, he experienced a liner seal failure in cylinder #1. This was not detected immediately as the NTF filter was actually removing 100% of the glycol / water that was leaking directly into the crankcase and preventing damage.