What is bypass and what is micro filtration?

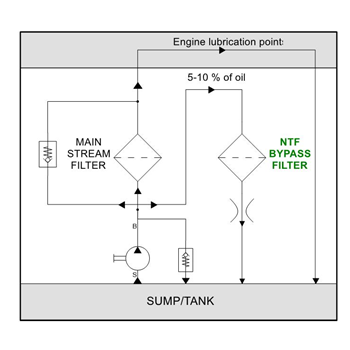

High efficiency bypass micro filtration utilizes a secondary circuit that combines bypass and micro filtration. Micro filtration provides additional filtering efficiency to the primary filtering system. NTF® filtration system utilizes patented compression technology in combination with depth media to ensure the highest filtration efficiencies.

The key to our micro filtration technology is in our filter element. The radial flow through the element offers a larger filtration surface area that prevents the channeling effect of filter elements design in a “honeycomb” style. This larger surface area holds more dirt and provides a more efficient filtering process and thereby filtering down to a submicron level leading to an overall cleanliness level superior to normal full flow filtration.

During the bypass process, an average of 1-2 liters/minute of fluid (vs.10-20 liters/minute in a full flow filter) passes through the filter, with no inline pressure drop. Because of the lower flow rate, the bypass system can be more restrictive, and able to remove a 99% of the very smallest particles in the fluid. Micro filtration results in superior fluid cleanliness for any lubrication or power transmission fluid system, including automatic transmission fluid (ATF), continuously variable transmission fluid (CVTF), dual clutch systems, engine oils, power steering fluids and hydraulic oils.

Principle bypass for motor transmission or hydraulic

Principle Offline filter systems

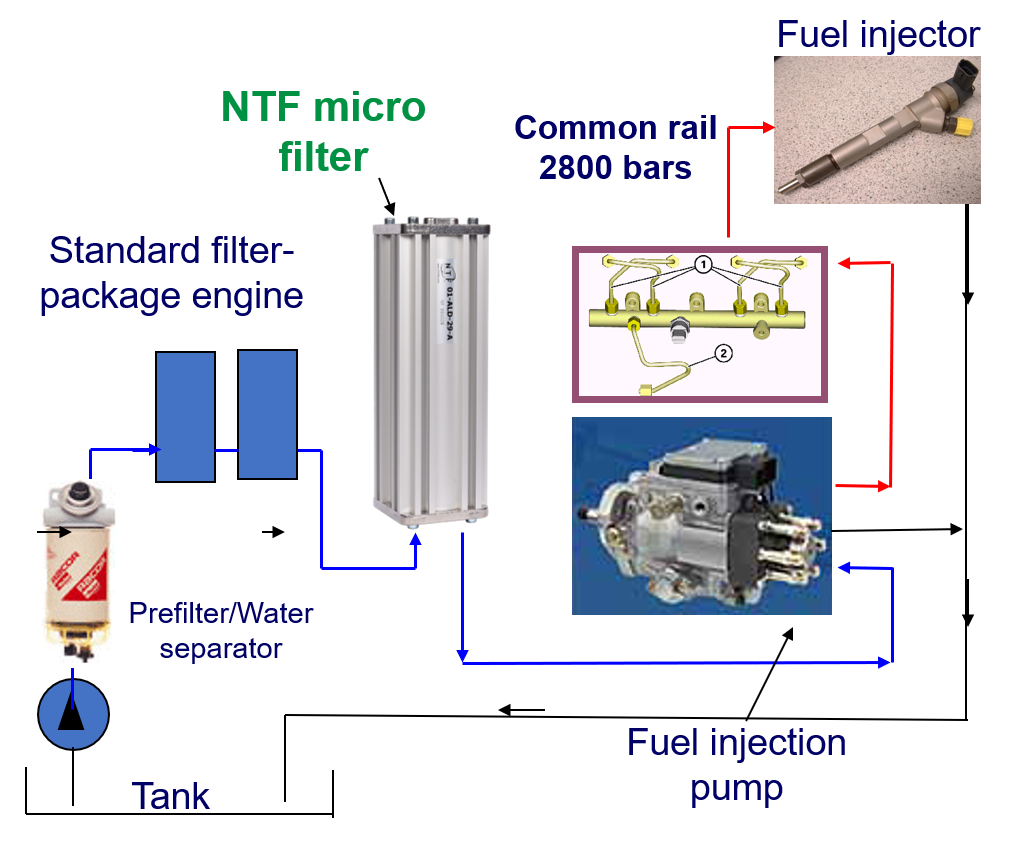

Principle inline fuel filter systems

Why do I need additional filtration (other than factory equipped)?

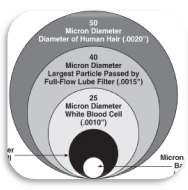

Why on Engine

Every engine is equipped with a standard or full flow filter, which removes the large particles that could cause immediate damage to the vehicle. But because an adequate flow of fluid through the filter must be ensured, the filter must be highly permeable. As a result of this restriction a full flow filter can not remove particles smaller than 10 to 15 micron. However, the majority of contaminants are much smaller than 10 micron and will therefore easily pass through a standard filter. 90% of engine wear is caused by particules between 2 and 5 micron in size.

The NTF filtration system removes contamination particles down to 0.5 micron in size. The reason for adding a NTF filter to your existing system is to clean the fluid, allowing the engine to run on clean oil 100% of the time. By keeping the oil clean you are eliminating over 90% of most engine wear.

Why on Hydraulics and transmissions

Electrically operated valves and cylinders have clearances around 4 microns in size while standard factory filters are usually designed to filter down to 8 microns ,sometimes even only up to 10 to 15 microns.

This makes it a matter of time until the hydraulic valves start to malfunction. They get sticky, less responsive or will block alltogether. To avoid these problems and to avoid high repair costs and downtime, additional filtration down to at least 4 microns is imperative. Failing to do so will result in high repair costs and downtime! In order for valves and cylinders to function properly an ISO-cleanliness class of minimum 19/16/13 is required. However in practice this usually is 21/20/15.

The NTF filtration system removes contamination particulates down to 0.5 micron in size. The reason for adding a NTF filter to your existing system is to clean the fluid, allowing the hydraulic system to run on clean oil 100% of the time. By keeping the oil clean you are eliminating over 80% of most common malfuctions in hydraulic systems and transmissions.

Benefits of NTF bypass micro filtration

Whether it is engine lube oil, automatic transmissions fluid, hydraulic oil or diesel fuel, the benefits of the NTF Radial Micro Filter are all based on maintaining a higher quality and cleanliness level of the oil and thereby reduced wear and tear of your equipment.

The great advantage of NTF Radial Micro Filters is that filtering takes place in a secondary circuit, enabling the highly efficiency NTF bypass filter to operate without disturbing the primary oil circuit. Thereby an efficiency which is 10 times better than any standard inline filter is achieved. This results in very clean oil and fewer breakdowns.

Advantages of cleaner oil:

- Fewer breakdowns

- Less wear and tear

- Oil can be used longer

- Frequency of servicing can be reduced

- Structural cost savings

- Longer service life of equipment

- Better performance

- Environmentally friendly

So in summary a lower total cost of ownership and a machine that lasts longer with fewer breakdowns!

The efect of bypass filter on the life expectancy of machine components

Life extension factors show the influence of moisture and oil cleanliness on the lifetime expectancy of critical components. Based on various studies by different parties, four tables are widely spread amongst maintenance engineers and lubrication specialist.

Many of them have improved an added micro filtration systems on their machines to give the machines a longer lifespan and that gave good results.

Example: If we take an oil sample from an existing hydraulic system and test it in a laboratory, resulting in a cleanliness code ISO 21/19/16 and by applying better filtration on the hydraulic system, we drop to an ISO 17/15/12. This means that the expected lifetime of the hydraulic components is 300%longer.

Why is it not factory instald?

There are two classic basic reasons: First, adding aftermarket products as factory equipment drives up the price of the products. Secondly, the manufacturers have planned obsolescence built into the engines to enable them to keep selling replacement parts and engines to you the consumer. Manufacturers are slowly changing their view however. They concentrate more and more on life time extension and low maintenance costs to gain and keep a competitive market position. Due to this trend micro filtration does gain their interest. In fact 2 large car manufacturers apply NTF filter systems on their automatic transmissions.

How to Evaluate Oil Filters and why is Beta ratio better than Filter efficiency?

Oil cleanliness is critical to reliable machinery, automobiles, hydraulics and fleet vehicles. It pays to work smart and make good decisions when evaluating and purchasing oil filters. Understanding how filters are tested and rated is key to your decision making process.

Studies show that when lube oil contaminant levels are low, wear rates and engine life can improve dramatically. High levels of contaminants in oil can impact fuel economy, lubricant life and create environmental issues.

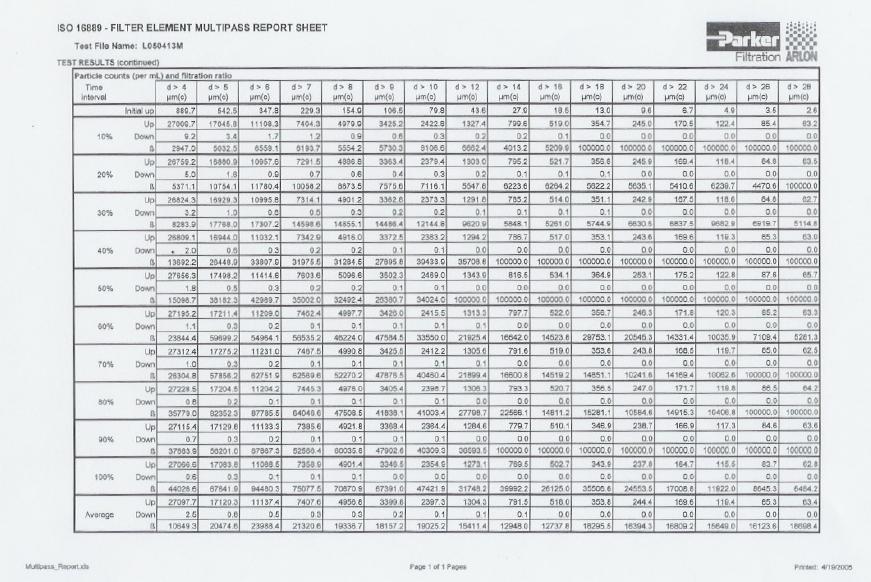

NTF Filter and the official Beta Ratio Test B 4 = 10649

NTF filter has had its filters officially tested by Parker filtration.

see here the official test document.

Oil filters can be tested in a variety of ways, but one of the most common methods is the beta ratio test. This test incorporates online particle counters positioned upstream and downstream of the filter, a continuous flow of test contaminant into the main system reservoir and oil flowing through the filter.

The beta ratio is calculated by dividing the number of particles larger than a certain size upstream of the filter by the number of particles of the same size downstream of the filter.

For example, you may have a beta ratio or a beta sub 5 (meaning particles larger than 5 microns) equal to 10. This means 10 particles upstream of the filter would be divided by 1 downstream of the filter.

Every filter will have multiple beta ratios. There could be a beta ratio for 2 microns, 5 microns, 10 microns, 50 microns, 100 microns, etc.

You