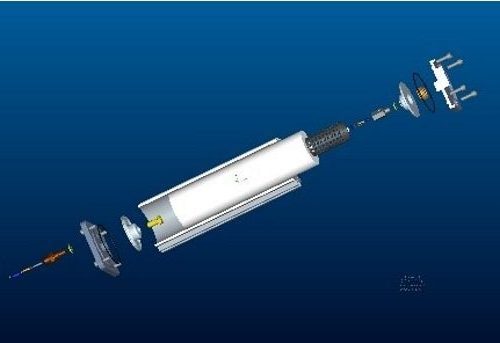

Filter replacement cartridge for AL, ALH, ALD, OLFS series

Filter cartridge

Filter efficiency

Beta ratio 4 micron

Beta ratio 2 micron

Retention value

Flow direction

Dimensions

Seals

Absorption capacity

F-09

99,7% @ 2 micron

Beta (ß) 4 > 10649

Beta (ß) 2 > 2335

0.5 micron

radial

Ø 78 x 90 mm

Buna NBR 70º

45 ml H2O

F-19

99,7% @ 2 micron

Beta (ß) 4 > 10649

Beta (ß) 2 > 2335

0.5 micron

radial

Ø 78 x 180 mm

Buna NBR 70º

90 ml H2O

F-29

99,7% @ 2 micron

Beta (ß) 4 > 10649

Beta (ß) 2 > 2335

0.5 micron

radial

Ø 78 x 300 mm

Buna NBR 70º

142 ml H2O

F-58

99,7% @ 2 micron

Beta (ß) 4 > 10649

Beta (ß) 2 > 2335

0.5 micron

radial

Ø 78 x 600 mm

Buna NBR 70º

284 ml H2O

AL series for engine, transmission and low pressure hydraulics

Filter type

Filter efficiency

Oil volume engine

Oil volume transmission

Oil volume hydraulic

Max. pressure

Max. temperature

Replacement cartridge

AL-09

Beta (ß) 4 > 10649

upto 10 liter

upto 15 liter

upto 30 liter

10 bar

120 °C

F-09

AL-19

Beta (ß) 4 > 10649

upto 20 liter

upto 30 liter

upto 60 liter

10 bar

120 °C

F-19

AL-29

Beta (ß) 4 > 10649

upto 35 liter

upto 50 liter

upto 100 liter

10 bar

120 °C

F-29

AL-58

Beta (ß) 4 > 10649

upto 70 liter

upto 100 liter

upto 200 liter

10 bar

120 °C

F-58

AL series engine, transmission , low pressure hydraulics

| Filter type Oil volume engine Oil volume transmission Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature |

AL-09 appr. 10 liter appr. 15 liter 110 x 110 x 144 mm 1,5 kg 0,62 liter M12 x 1,5 7 bar 120 °C |

| Filter type Oil volume engine Oil volume transmission Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature |

AL-19 appr. 20 liter appr. 30 liter 110 x 110 x 234 mm 2,2 kg 1,13 liter M12 x 1,5 7 bar 120 °C |

| Filter type Oil volume engine Oil volume transmission Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature |

AL-29 appr. 35 liter appr. 50 liter 110 x 110 x 354 mm 3,2 kg 1,6 liter M12 x 1,5 7 bar 120 °C |

| Filter type Oil volume engine Oil volume transmission Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature |

AL-58 appr. 70 liter appr. 100 liter 110 x 110 x 654 mm 6,4 kg 3,2 liter M12 a 1,5 7 bar 120 °C |

Filter cartridge

Flow direction

Weight

Filter surface

Filter efficiency

Dimensions

Seals

Absorption capacity

Flow rate (nom.)

F-09

radial

160 g

221 cm2

Beta (ß) 4 > 10649

Ø 78 x 90 mm

Buna NBR 70º

45 ml H2O

1,6 l/min

F-19

radial

300 g

442 cm2

Beta (ß) 4 > 10649

Ø 78 x 180 mm

Buna NBR 70º

90 ml H2O

1,6 l/min

F-29

radial

460 g

735 cm2

Beta (ß) 4 > 10649

Ø 78 x 300 mm

Buna NBR 70º

142 ml H2O

1,6 l/min

F-58

radial

920 g

1470 cm2

Beta (ß) 4 > 10649

Ø 78 x 600 mm

Buna NBR 70º

284 ml H2O

1,6 l/min

AL Serie

The low pressure AL filter systems are frequently used on engines, transmissions and low pressure hydraulic systems (upto 10 bar). Particularly in the heavy-duty segment vehicle and fleet owners have a significant interest in reducing maintenance costs. An example of this is the use of the AL-29 unit for protecting the power-shifts/ hydraulic transmission on tractors. Other applications include heavy-duty trucks, construction and off-highway vehicles, marine applications and other agricultural vehicles.

The AL filter systems are equipped with a restriction in order to prevent the oil pressure to drop beneath the required minimum as a result of the created bypass.

Advantages of cleaner oil:

- Fewer breakdowns

- Less wear and tear

- Oil can be used longer

- Frequency of servicing can be reduced

- Structural cost savings

- Longer service life of equipment

- Improved performance

- Environmentally friendly

ALH series for high pressure hydraulics

Filter Type

Filter efficiency

Sump volume in

Flow control valve

Max. operating pressure

Min. operating pressure

Maximum temperature

Indicator

Bypass Setting

Nominal Flow

Replacement cartridge

ALH-09/420

– Beta (ß) 4 > 10649 –

225 liter

420 Bar

10 Bar

100 °C

pressure gauge

5.5 Bar

1,0 ltr/min

F-09

ALH-19/420

– Beta (ß) 4 > 10649 –

450 liter

420 Bar

10 Bar

100 °C

pressure gauge

5.5 Bar

1,5 ltr/min

F-19

ALH-29/420

– Beta (ß) 4 > 10649 –

750 liter

420 Bar

10 Bar

100 °C

pressure gauge

5.5 Bar

2.1 ltr/min

F-29

ALH-58/420

– Beta (ß) 4 > 10649 –

1500 liter

420 Bar

10 Bar

100 °C

pressure gauge

5.5 Bar

4.2 ltr/min

F-58

ALH series high pressure hydraulics 420 Bar

| Filter Type Filter efficiency Sump volume in Dimensions filter element Material filter housing Max. operating pressure flow control valve Min. operating pressure flow control valve Maximum temperature Maximum viscosity Indicator Connection Pressure side I.D. Pressure hose Return Connection I.D. Return hose Seals Bypass Setting Nominal Flow Connections monitor Weight Dimensions in mm |

ALH-09/420 – Beta (ß) 4 > 10649 – 225 liter Ø 78 x 90 mm – Anodized Alum. – 420 Bar10 Bar100 °C 180 cSt manometerJIC UNF 9/16-18 10 mm M12x1,5 12 mm Buna NBR 5.5 Bar 1,0 ltr/min N.A. 1,8 kg 110x145x170mm |

| Filter Type Filter efficiency Sump volume in Dimensions filter element Material filter housing Max. operating pressure flow control valve Min. operating pressure flow control valve Maximum temperature Maximum viscosity Indicator Connection Pressure side I.D. Pressure hose Return Connection I.D. Return hose Seals Bypass Setting Nominal Flow Connections monitor Weight Dimensions in mm |

ALH-19/420 – Beta (ß) 4 > 10649 – 450 liter Ø 78 x 180 mm – Anodized Alum. – 420 Bar10 Bar100 °C 180 cSt manometerJIC UNF 9/16-18 10 mm M12x1,5 12 mm Buna NBR 5.5 Bar 1,5 ltr/min N.A. 1,8 kg 110x145x170mm |

| Filter Type Filter efficiency Sump volume in Dimensions filter element Material filter housing Max. operating pressure flow control valve Min. operating pressure flow control valve Maximum temperature Maximum viscosity Indicator Connection Pressure side I.D. Pressure hose Return Connection I.D. Return hose Seals Bypass Setting Nominal Flow Connections monitor Weight Dimensions in mm |

ALH-29/420 – Beta (ß) 4 > 10649 – 750 liter Ø 78 x 300 mm – Anodized Alum. – 420 Bar10 Bar100 °C 180 cSt manometerJIC UNF 9/16-18 10 mm M12x1,5 12 mm Buna NBR 5.5 Bar 2.1 ltr/min N.A. 1,8 kg 110x145x170mm |

| Filter Type Filter efficiency Sump volume in Dimensions filter element Material filter housing Max. operating pressure flow control valve Min. operating pressure flow control valve Maximum temperature Maximum viscosity Indicator Connection Pressure side I.D. Pressure hose Return Connection I.D. Return hose Seals Bypass Setting Nominal Flow Connections monitor Weight Dimensions in mm |

ALH-58/420 – Beta (ß) 4 > 10649 – 1500 liter Ø 78 x 600 mm – Anodized Alum. – 420 Bar10 Bar100 °C 180 cSt manometerJIC UNF 9/16-18 10 mm M12x1,5 12 mm Buna NBR 5.5 Bar 4.2 ltr/min N.A. 1,8 kg 110x145x170mm |

Filter cartridge

Flow direction

Weight

Filter surface

Filter efficiency

Dimensions

Seals

Absorption capacity

F-09

radial

160 g

221 cm2

Beta (ß) 4 > 10649

Ø 78 x 90 mm

Buna NBR 70º

45 ml H2O

F-19

radial

300 g

442 cm2

Beta (ß) 4 > 10649

Ø 78 x 180 mm

Buna NBR 70º

90 ml H2O

F-29

radial

460 g

735 cm2

Beta (ß) 4 > 10649

Ø 78 x 300 mm

Buna NBR 70º

142 ml H2O

F-58

radial

920 g

1470 cm2

Beta (ß) 4 > 10649

Ø 78 x 600 mm

Buna NBR 70º

284 ml H2O

ALH Series

The ALH-series represent our bypass hydraulic filtration line and is used in many applications, including off-road mobile equipment, heavy-duty vehicles, stationary cranes, stationary hydraulic systems, fork lifts and industrial equipment. It is also used in sophisticated flight simulators, as well as in test stands where cleanliness is crucial.

These systems are based on the AL-series and are equipped with an external pressure controld flow regulator allowing a maximum operating pressure up to

420 Bar. The design guarantees a constant flow and pressure in the filter system, regardless of the flow and pressure outside of the filter system. As usual, to prevent internal leakages, the ALH filters have been equipped with NTF’s patented pressure plates. The filter element is protected by an integrated bypass valve (5,5 Bar) it protects the filter element against pressure spikes, which are fatal to filters.

By using the NTF® filter system, solid contamination particles can be reduced up to 99%. Since the oil is kept much cleaner, the number of component failures and breakdowns decreases notably. As a result, the operational efficiency of your machines and installations improves. Furthermore, the

life time of your expensive equipment will be prolonged, since cleaner oil reduces wear significantly.

In short, by using an NTF® filter system, you will experience significant structural savings on the cost of ownership. .

Advantages of cleaner oil:

- Fewer breakdowns

- Less wear and tear

- Longer oil life

- Frequency of servicing can be reduced

- Structural cost savings

- Longer service life of equipment

- Improved performance

- Environmentally friendly

ALD series for fuel

Filter type

Filter efficiency

Fuel pump flow rate nom

Max. pressure

Max. temperature

Bypass setting

ALD-09

Beta (ß) 4 > 10649

6 l/min

7 bar

100 °C

1,0 bar

ALD-19

Beta (ß) 4 > 10649

8 l/min

7 bar

100 °C

1,0 bar

ALD-29

Beta (ß) 4 > 10649

10 l/min

7 bar

100 °C

1,0 bar

ALD-58

Beta (ß) 4 > 10649

12 l/min

7 bar

100 °C

1,0 bar

ALD series Fuel

| Filter type Fuel pump flow rate nom Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature Bypass setting Hose diameter |

ALD-09 6 l/min 110 x 110 x 144 mm 1,5 kg 0,62 liter M12 x 1,5 7 bar 100 °C 1,0 bar 10 mm |

| Filter type Fuel pump flow rate nom Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature Bypass setting Hose diameter |

ALD-19 8 l/min 110 x 110 x 234 mm 2,2 kg 1,13 liter M12 x 1,5 7 bar 100 °C 1,0 bar 10 mm |

| Filter type Fuel pump flow rate nom Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature Bypass setting Hose diameter |

ALD-29 10 l/min 110 x 110 x 354 mm 3,2 kg 1,6 liter M12 x 1,5 7 bar 100 °C 1,0 bar 10 mm |

| Filter type Fuel pump flow rate nom Dimensions Weight Volume Connection IN / OUT Max. pressure Max. temperature Bypass setting Hose diameter |

ALD-58 12 l/min 110 x 110 x 654 mm 6,4 kg 3,2 liter M12 x 1,5 7 bar 100 °C 1,0 bar 10 mm |

Filter cartridge

Flow direction

Weight

Filter surface

Filter efficiency

Dimensions

Seals

Absorption capacity

F-29

radial

460 g

735 cm2

Beta (ß) 4 > 10649

Ø 78 x 300 mm

Buna NBR 70º

142 ml H2O

F-29

radial

460 g

735 cm2

Beta (ß) 4 > 10649

Ø 78 x 300 mm

Buna NBR 70º

142 ml H2O

F-58

radial

920 g

1470 cm2

Beta (ß) 4 > 10649

Ø 78 x 600 mm

Buna NBR 70º

284 ml H2O

F-58

radial

920 g

1470 cm2

Beta (ß) 4 > 10649

Ø 78 x 600 mm

Buna NBR 70º

284 ml H2O

ALD Ultra efficient fuel filter

The introduction of common rail diesel injection systems, with extremely high injection pressures and sensitive components, has led to higher cleanliness requirements to the fuel. Particles in the fuel cause excessive wear, a limited life-time and an increase in injection system failures. The contamination levels of standard fuel increase the need for an effective filter even more.

The ALD fuel filters are installed directly in the main circuit, preferably directly after the standard fuel filters. To be assured of optimal filtration, the fuel system needs to be fitted with a proper water separator. The ALD fuel filters are equipped with an internal bypass, thereby ensuring an unrestricted flow of fuel through the entire fuel system under all circumstances.

Extremely high filter efficiency

The ALD fuel filter system has a filter efficiency of 99,95 % and has proven to provide an excellent filtering performance. Cleaner fuel leads to demonstrably fewer breakdowns and will ultimately reduce the cost of ownership of the total equipment.

Advantages of cleaner fuel:

- Fewer breakdowns

- Less wear and tear

- Structural cost savings

- Longer service life of equipment

- Improved performance

- Environmentally friendly

OLFS series for bulk tanks. Hydraulics, lube oil and fuel

Filter type

Filter efficiency

Sump volume (directive)

Nominal flow

Max. temperature

Max. Viscosity

Indicator

Bypass setting

Connections monitor

Trolley option

Pump:

Type

Max. Temperature

Electric motor:

Power supply

ATEX electric motor

OLFS-29/1

Beta (ß) 4 > 10649

1350 litre

– depending on application –

80 °C

– depending on application –

pressure gauge

5.5 Bar

1/8 BSP>M16X2

no

gear pump

80 °C

– several tensions possible –

– optional –

OLFS-29/2

Beta (ß) 4 > 10649

2700 Liter

– depending on application –

80 °C

– depending on application –

pressure gauge

5.5 Bar

1/8 BSP > M16X2

yes

gear pump

80 °C

– several tensions possible –

– optional –

OLFS-58/1

Beta (ß) 4 > 10649

2700 litre

– depending on application-

80 °C

– depending on application –

pressure gauge

5.5 Bar

1/8 BSP > M16X2

No

gear pump

80 °C

– several tensions possible –

– optional –

OLFS-58/2

Beta (ß) 4 > 10649

5400 Liter

– depending on application –

80 °C

– depending on application –

pressure gauge

5.5 Bar

1/8 BSP > M16X2

Yes

gear pump

80 °C

– several tensions possible –

– optional –

OLFS Series

The NTF Off Line Filter System, (OLFS), can be used with any hydraulic, lubrication or transmission system in virtually any market or industry. The system is equipped with its own motor-pump combination, which means that the system pressures and specifications remain in conformance with the values specified by the manufacturer. The motor-pump combination pumps oil from the reservoir (or engine sump), the dirty oil is then pumped through the filter and clean oil is returned to the reservoir.

The NTF Off Line Filter System is based on a modular and especially designed manifold that integrates all of the oil channels. So leakages from vibrations or poorly connected pipes are a thing of the past. Because the whole system is mounted on a base plate, it can be quickly and easily installed in your system.

All versions are available with a variety of gear pumps and electromotors and are built specifically for your application. The OLFS-58/6 unit can also be fitted with a water separator, making it suitable for fuel applications.

Advantages of cleaner oil:

- Fewer breakdowns

- Less wear and tear

- Longer oil life

- Frequency of servicing can be reduced

- Structural cost savings

- Longer service life of equipment

- Improved performance

- Environmentally friendly

OLFS/6 Series for Industrial hydraulic, transmission, bulk tank

Filter type

Filter efficiency

Nominal flow

Max. temperature

Indicator

Bypass setting

Connections monitor

Complete unit Weight

Dimensions (hxwxd)

Particle counter

Pump type

Displacement

Max. Temperature

Electric motor power supply

ATEX electric motor

OLFS-58/6

Beta (ß) 4 > 10649

Depending on application

80° Celsius

Press. gauge

5.5 Bar

1/8 BSP > M16X2

90 kg approx.

1020 x 600 x 320 mm

– optional –

Gear pump

– several pumps possible –

80° Celsius

– several tensions possible –

– optional –

OLFS Series

The NTF Off Line Filter System, (OLFS), can be used with any hydraulic, lubrication or transmission system in virtually any market or industry. The system is equipped with its own motor-pump combination, which means that the system pressures and specifications remain in conformance with the values specified by the manufacturer. The motor-pump combination pumps oil from the reservoir (or engine sump), the dirty oil is then pumped through the filter and clean oil is returned to the reservoir.

The NTF Off Line Filter System is based on a modular and especially designed manifold that integrates all of the oil channels. So leakages from vibrations or poorly connected pipes are a thing of the past. Because the whole system is mounted on a base plate, it can be quickly and easily installed in your system.

Advantages of cleaner oil:

- Fewer breakdowns

- Less wear and tear

- Longer oil life

- Frequency of servicing can be reduced

- Structural cost savings

- Longer service life of equipment

- Improved performance

- Environmentally friendly

OLFS/6 Series FOR FUEL APPLICATIONS

Filter type

Filter efficiency

Nominal flow

Max. temperature

Max. viscosity

Indicator

Bypass setting

Pump type

Displacement

Max. Temperature

Electric motor power supply

Water Separator

Manual drainvalve

Sight glass

Differential pressure gauge

Complete unit weight

Dimensions (hxwxd)

OLFS-58/6-B-380/1,5-25-FBO14(60356)

Beta (ß) 4 > 10649

40 l/min.

80° Celsius

10 cSt

press. gauge

5.5 Bar

gear pump

25cc

80° Celsius

– several tensions possible –

FBO-14

Yes

Yes

Yes

96 kg

102 x 66 x 38 cm

It is a known fact that an engine’s fuel consumption increases as it ages; this is a result of wear of the fuel system and the engine.

This wear reduces the engine’s capacity, as a result of which more throttle is required to achieve the same performance.

By removing a significant amount of wear particles from the engine oil and fuel, the ageing process is slowed down dramatically.

As a result, both the lubrication of the engine and the reaction time in the fuel system remain in optimal condition.

This also means optimal fuel consumption is achieved.

Ultra efficient fuel filter

The introduction of common rail diesel injection systems, with extremely high injection pressures and sensitive components, has led to higher cleanliness requirements of the fuel. Particles in the fuel cause excessive wear, a limited life-time and an increase in

injection system failures. The contamination levels of standard fuel increase the need for an effective filter even more.

The OLFS fuel filter unit is installed in the line from tank to the filling point. It replaces the original pump. Before the fuel enters the vehicle/truck all fuel is cleaned from water and wear particles and your expensive fuel pumps and injectors are protected.

OLFS ATEX serie hydraulics, engine, transmission, bulk tanks,

Filter type

Filter efficiency

Sump volume (directive)

Nominal flow

Max. temperature

Max. Viscosity

Indicator

Bypass setting

Connections monitor

Pump type

Electric motor:

Power supply

Weight

Dimensions (hxwxd)

OLFS-29/1

Beta (ß) 4 > 10649

21350 litre

– depending on application –

80 °C

– depending on application –

press. gauge

5.5 Bar

1/8 BSP > M16X

gear pump

ATEX

– several tensions possible –

21 kg

500x340x190 mm

OLFS-58/1

Beta (ß) 4 > 10649

2700 litre

– depending on application –

80 °C

– depending on application –

press. gauge

5.5 Bar

1/8 BSP > M16X2

gear pump

ATEX

– several tensions possible –

23,7 kg

800x340x190 mm

– OLFS-58/2

Beta (ß) 4 > 10649

5400 Liter

– depending on application –

80 °C

– depending on application –

– pressure gauge –

5.5 Bar

1/8 BSP > M16X2

gear pump

ATEX

– several tensions possible –

31 kg

800x445x200 mm

– OLFS-58/6

Beta (ß) 4 > 10649

20.000 Liter

– depending on application –

80 °C

– depending on application –

pressure gauge

5.5 Bar

1/8 BSP > M16X2

gear pump

ATEX

– several tensions possible –

31 kg

800x445x200 mm

OLFS Series

The NTF Off Line Filter System, (OLFS), can be used with any hydraulic, lubrication or transmission system in virtually any market or industry. The system is equipped with its own motor-pump combination, which means that the system pressures and specifications remain in conformance with the values specified by the manufacturer. The motor-pump combination pumps oil from the reservoir (or engine sump), the dirty oil is then pumped through the filter and clean oil is returned to the reservoir.

The NTF Off Line Filter System is based on a modular and especially designed manifold that integrates all of the oil channels. So leakages from vibrations or poorly connected pipes are a thing of the past. Because the whole system is mounted on a base plate, it can be quickly and easily installed in your system.

All versions are available with a variety of gear pumps and electromotors and are built specifically for your application. The OLFS-58/6 unit can also be fitted with a water separator, making it suitable for fuel applications.

Reference letter

OLFS Ultra efficiënt Polish System for (Bio) Fuel applications

Filter type

Filter efficiency

Nominal flow

Max. temperature

Max. viscosity

Bypass setting

Indicator

Pump Type

Displacement

Manual filling pump type

Electric motor power supply

Water Separator Separ

Manual drainvalve

Sight glass

De-Bug Type :

Manual drainvalve

Air relief valve

Complete unit weight

Dimensions (hxwxd)

Fuel (Bio)

Beta (ß) 4 > 10649

10 l./min.

80 °C

10 cSt

3 bar

press. gauge

gear pump

– several pumps possible

Separ EVO-hfp25

– several tensions possible –

Separ

Yes

Yes

1500

Yes

Yes

55 KG

110x66x45 cm

Ultra efficient Polish System

Fuel / water seperator / bacteria killer

It is a known fact that an engine’s fuel consumption increases as it ages; this is a result of wear of the fuel system and the engine.This wear reduces the engine’s capacity, as a result of which more throttle is required to achieve the same performance.

By removing a significant amount of wear particles from the engine oil and fuel, the ageing process is slowed down dramatically.As a result, both the lubrication of the engine and the reaction time in the fuel system remain in optimal condition.

This also means optimal fuel consumption is achieved.

The need for an Ultra efficient fuel filter

The introduction of common rail diesel injection systems, with extremely high injection pressures and sensitive components, has led to higher cleanliness requirements of the fuel. Particles in the fuel cause excessive wear, a limited life-time and an increase in injection system failures. The contamination levels of standard fuel increase the need for an effective filter even more.

The OLFS fuel filter unit is installed in the line from tank to the filling point or for circulating in a storage tank. Before the fuel enters the vehicle/truck all fuel is cleaned from water and wear particles and your expensive fuel pumps and injectors are protected.

Concrete Advantages of Cleaner Fuel:

• Fewer breakdowns

• Less wear and tear

• Structural cost savings

• Stopping bacteria growth

• Longer service life of equipment

• Improved performance

• Environmentally friendly

• Separate water

NTF Polish systeem Lower Fuel Consumption, that’s what it’s about!

OLFS portable series flush units for oil and fuel

Filter type

Filter efficiency

Sump volume (directive)

Nominal flow

Max. temperature

Max. Viscosity

Indicator

Bypass setting

Connections monitor

Pump type

Electric motor power supply

Weight

Dimensions (hxwxd)

Trolley option

OLFS-58/2

Beta (ß) 4 > 10649

– depending on application –

– depending on application –

80 °C

– depending on application –

– pressure gauge –

5.5 Bar

1/8 BSP > M16X2

gear pump

– several tensions possible –

31 kg

800x445x200 mm

yes

OLFS Series

The NTF Off Line Filter System, (OLFS), can be used with any hydraulic, lubrication or transmission system in virtually any market or industry. The system is equipped with its own motor-pump combination, which means that the system pressures and specifications remain in conformance with the values specified by the manufacturer. The motor-pump combination pumps oil from the reservoir (or engine sump), the dirty oil is then pumped through the filter and clean oil is returned to the reservoir.

The NTF Off Line Filter System is based on a modular and especially designed manifold that integrates all of the oil channels. So leakages from vibrations or poorly connected pipes are a thing of the past. Because the whole system is mounted on a base plate, it can be quickly and easily installed in your system.

All versions are available with a variety of gear pumps and electromotors and are built specifically for your application. The OLFS-58/6 unit can also be fitted with a water separator, making it suitable for fuel applications.

Flush units for hydraulic transmission of tractors

Filter type

Filter efficiency

Connection pressure hose

Connection return hose

Installation time

Duration 100 Liter flushing

Max. pressure system

Max. temperature

Max. viscosity

Setting bypass valve

Setting non-return valve

Setting flow control valve

Indicator

Weight

01-FLUSH-58/2-A-14-3-c

Beta (ß) 4 > 10649

Quick release coupling

Quick release coupling

1 minute

2 hours

25 Bar

90 °C

46 Cst.

3 Bar

0.2 Bar

14 lpm

differential pressure gauge

20 KG

01-FLUSH-58-2-A14-3-C Series

For over 40 years tractor owners and dealers have been installing our well-known AL-29-A bypass micro filter to protect the hydraulic transmission from break-down and to improve performance.

Also flushing the hydraulic system after repairs with our offline system OLFS-58 has become common practice amongst CNH dealers.

Flushing is strongly recommended after any break down and repair of the drive-line, brakes and/or the hydraulic system to avoid malfunctioning proportional valves caused by contamination.

It can also be used to flush any new tractor before delivery to the customer or to extend the oil change interval.

Cleaner oil leads to less malfunctions and warranty claims and increases customer satisfaction.

In cooperation with CNH tractor dealers we have now developed an improved, tailor-made service kit.

This NTF flush unit allows for clean and easy installation within 1 minute and will flush a hydraulic system of 100 liter within 2 hours. With the specially designed bracket it can be quickly and easily installed in the slots on the back of the tractor. The hoses have been fitted with quick release couplings to allow for quick and clean connection to the valve block.

With a permanently installed AL-29-A bypass micro filter on the tractor and the use of the flush unit after repairs, recurring warranty claims are a thing of the past

NTF Filter Flush unit for tractor hydraulics English